Asbestos Coatings

Encapsulation System

ADVANCED ENCAPSULATION COATING SYSTEM – Please contract us for further information as these products are currently special order. Although we do carry a small amount of stock.

This is a 3 part System:

Encapsulation Coat, Subflex 1000 High Build Base Coat and Hydrophobic Finish Coat combined together have unique properties ensuring excellent performance on properly prepared asbestos surfaces.

1. Encapsulation Coat is a low viscosity nano particle primer, specifically designed to penetrate and bind asbestos. It forms a perfect surface for the Subflex 1000 High Build Base Coat to adhere to. This should be applied at 10-12 square meters per litre.

2. Subflex 1000 is a water based High Build Acrylic finish coat for exterior surfaces. Its unique formulation imparts a high degree of water resistance and elastomeric properties making it an ideal final finish over cementitious substrates including Asbestos, concrete blocks and EIFS. The elastomeric properties of Subflex 1000 will help minimize water ingress resulting from small substrate surface cracking. This coating should be applied at 700 microns per coat. Two coats are required to attain a 1mm dry film build required in this system.

3. Hydrophobic Finish Coat is high gloss, high UV resistance and should be applied at 5 square meters per litre to give a film thickness of 200 microns wet film build. The correct film thickness is important as it will impact on the life and effectiveness of the coating. Hydrophobic Finish Coat is available in a variety of colours but its recommended colour is white.

White is recommended along with a high gloss, as this combination reflects the most light to minimise heat build up in the asbestos sheet. Minimising the heating effect reduces the movement (expansion and contraction) of the asbestos and reduces the lapped sheets rubbing together so creating asbestos dust. This coating helps to reduce cooling costs as the white colour reflects the suns heat. Available in White.

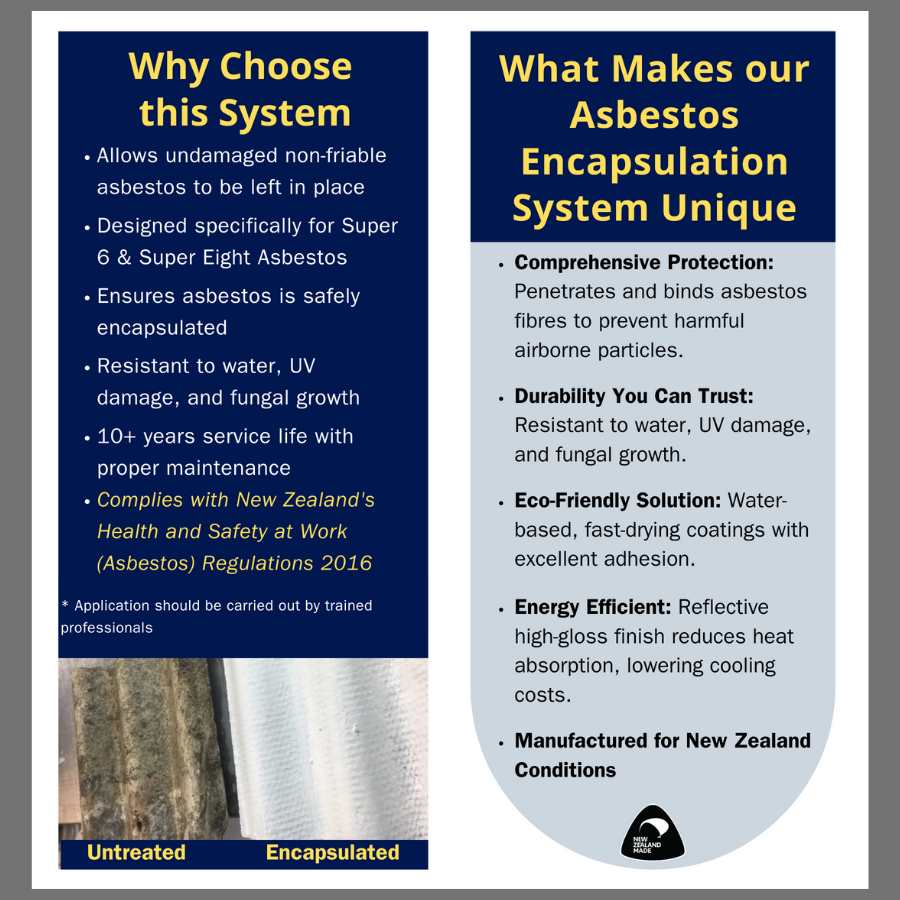

Why Choose this System:

- Allows undamaged non-friable asbestos to be left in place

- Designed specifically for Super 6 & Super Eight Asbestos

- Ensures asbestos is safely encapsulated

- Resistant to water, UV damage, and fungal growth

- 10+ years service life with proper maintenance

- Complies with New Zealand’s Health and Safety at Work (Asbestos) Regulations 2016

Click here to download: Asbestos Encapsulation System Guide

This product is Special Order – Please Call to discuss your requirements. We do carry a small amount of stock.

- 30 days Return Policy

- 100% Secure Checkout

- Visa & Mastercard

- Account2Account

- AfterPay

Description

ADVANCED ENCAPSULATION COATING SYSTEM – Please contract us for further information as these products are currently special order. Although we do carry a small amount of stock.

This is a 3 part System:

Encapsulation Coat, Subflex 1000 High Build Base Coat and Hydrophobic Finish Coat combined together have unique properties ensuring excellent performance on properly prepared asbestos surfaces.

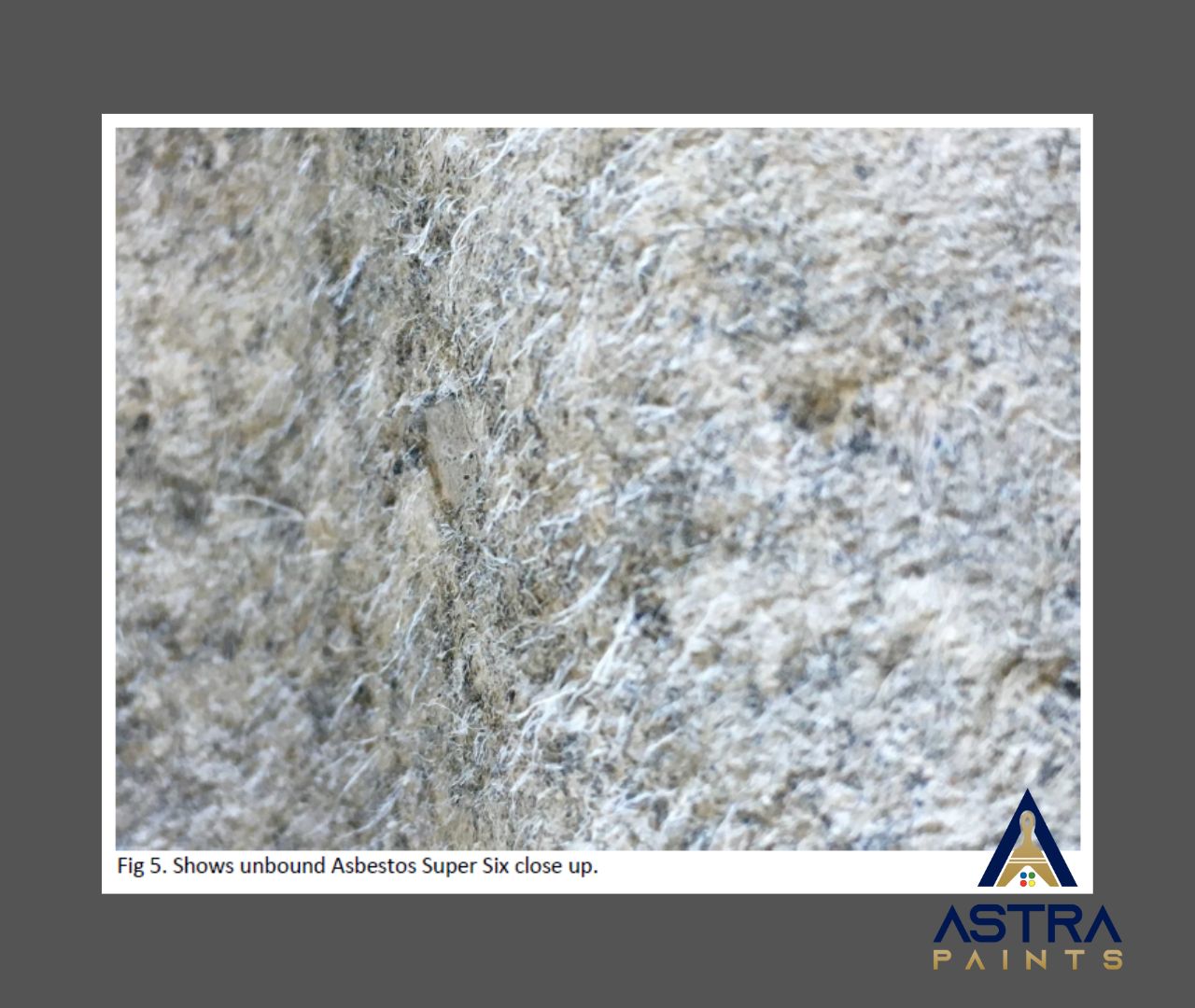

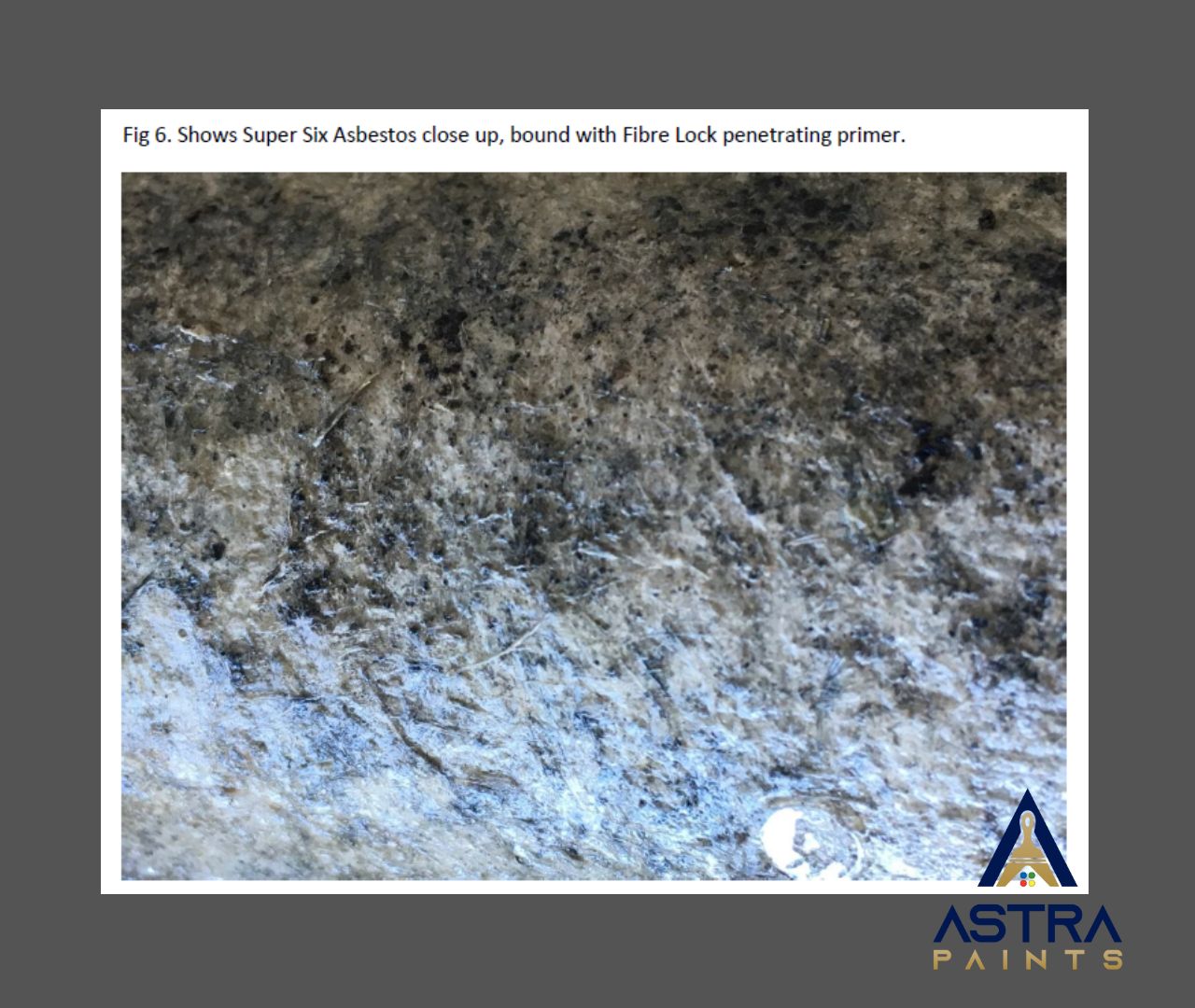

1. Encapsulation Coat is a low viscosity nano particle primer, specifically designed to penetrate and bind asbestos. It forms a perfect surface for the Subflex 1000 High Build Base Coat to adhere to. This should be applied at 10-12 square meters per litre.

2. Subflex 1000 is a water based High Build Acrylic finish coat for exterior surfaces. Its unique formulation imparts a high degree of water resistance and elastomeric properties making it an ideal final finish over cementitious substrates including Asbestos, concrete blocks and EIFS. The elastomeric properties of Subflex 1000 will help minimize water ingress resulting from small substrate surface cracking. This coating should be applied at 700 microns per coat. Two coats are required to attain a 1mm dry film build required in this system.

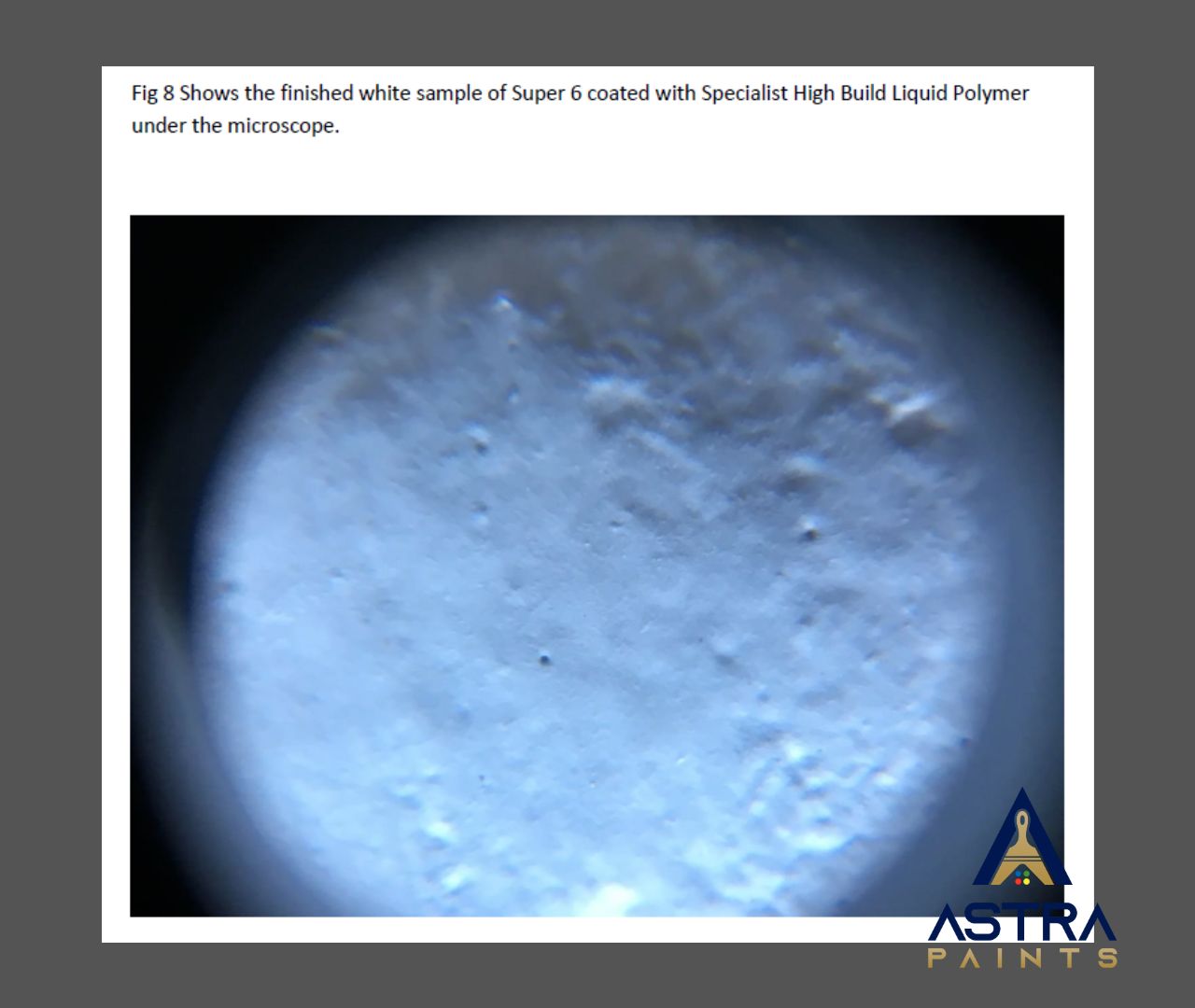

3. Hydrophobic Finish Coat is high gloss, high UV resistance and should be applied at 5 square meters per litre to give a film thickness of 200 microns wet film build. The correct film thickness is important as it will impact on the life and effectiveness of the coating. Hydrophobic Finish Coat is available in a variety of colours but its recommended colour is white.

White is recommended along with a high gloss, as this combination reflects the most light to minimise heat build up in the asbestos sheet. Minimising the heating effect reduces the movement (expansion and contraction) of the asbestos and reduces the lapped sheets rubbing together so creating asbestos dust. This coating helps to reduce cooling costs as the white colour reflects the suns heat. Available in White.

Why Choose this System:

- Allows undamaged non-friable asbestos to be left in place

- Designed specifically for Super 6 & Super Eight Asbestos

- Ensures asbestos is safely encapsulated

- Resistant to water, UV damage, and fungal growth

- 10+ years service life with proper maintenance

- Complies with New Zealand’s Health and Safety at Work (Asbestos) Regulations 2016

Click here to download: Asbestos Encapsulation System Guide

This product is Special Order – Please Call to discuss your requirements. We do carry a small amount of stock.

Related products

-

Anticorrosive Primer Grey

$249.00

Oil Based 10LAdd to cart -

Sale!

Poolkote

Chlorinated Rubber 10L$534.45Original price was: $534.45.$475.00Current price is: $475.00.Select options This product has multiple variants. The options may be chosen on the product page -

Rust Con

$69.00 – $625.00Price range: $69.00 through $625.00

Rust Convertor

All SizesSelect options This product has multiple variants. The options may be chosen on the product page -

Roofrite Key Coat

$260.00

Penetrative Sealer 20LAdd to cart